Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

In early October 2025, the world’s attention was on another major milestone in the electric‑vehicle (EV) revolution. Governments in Europe, Asia, and North America announced fresh incentives and stricter emissions standards, while automotive giants—including Tesla, BYD, and Hyundai—rolled out new models that promise longer range, higher performance, and lower costs. This wave of enthusiasm, reported by Bloomberg, Reuters, and the World Economic Forum, is reshaping how we think about transportation. But behind the sleek exteriors and cutting‑edge batteries lies an unsung hero that keeps every electric drive moving smoothly: the gear motor, or reducer motor.

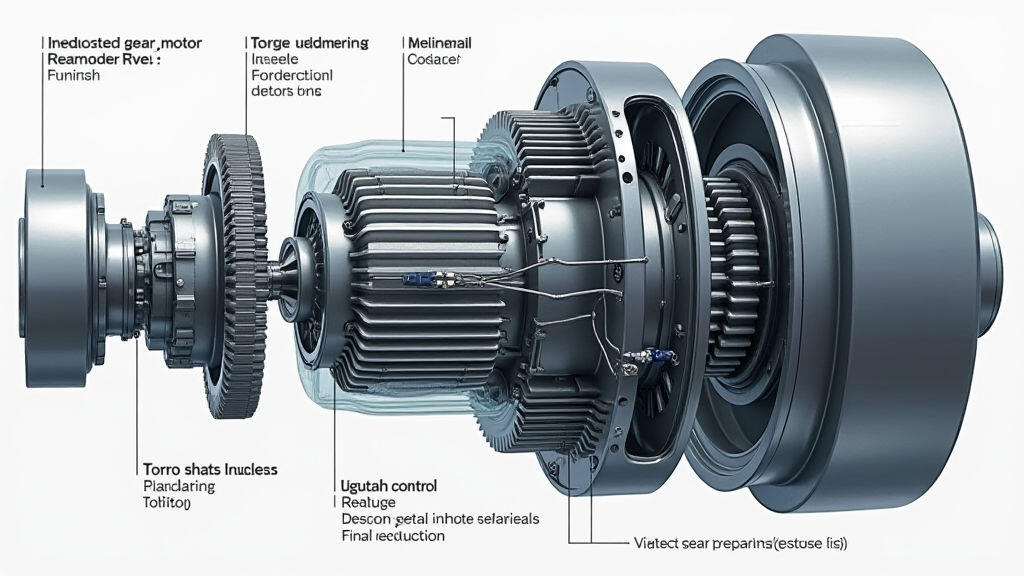

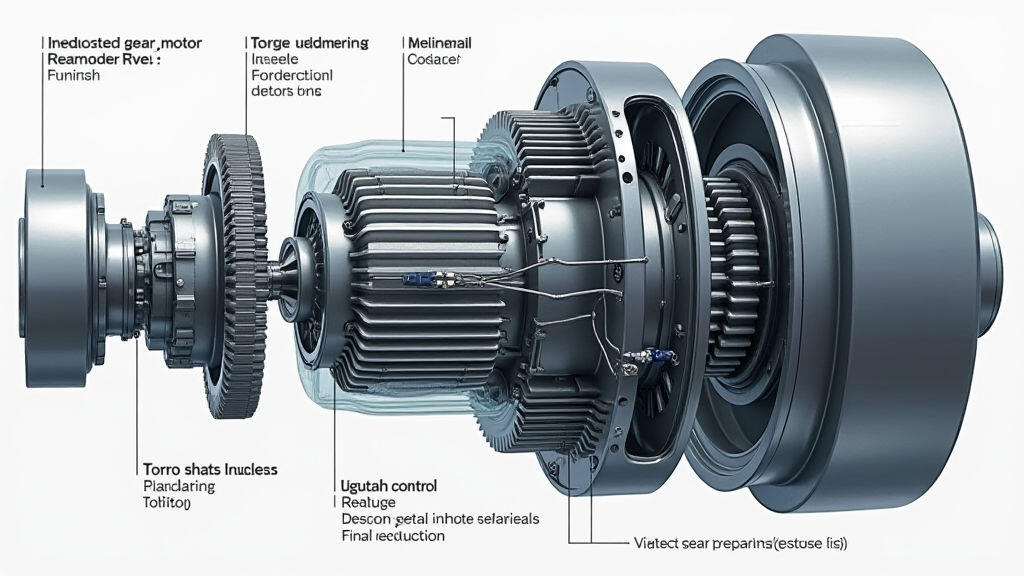

A modern electric car never moves directly from the battery to the wheels. Instead, the electric motor delivers high‑speed, low‑torque power that must be converted to a speed and force suitable for driving a vehicle. Gear motors perform this critical conversion by reducing the motor’s high rotation rate while increasing torque, allowing the car to accelerate efficiently from a standstill and climb steep gradients. Because electric motors can produce maximum torque at zero RPM, a gear motor can keep the engine from spinning too fast, protecting the battery and improving overall power delivery.

The push for longer range drives the demand for more efficient gear motors. In the past decade, gear motor manufacturers have reduced friction and added advanced materials to minimize losses. High‑performance gear motors today achieve efficiencies above 97 %, significantly cutting the energy that would otherwise be dissipated as heat. As automakers look to squeeze every kilowatt-hour of battery life into their vehicles, a “smart” gear motor becomes as essential as the battery itself.

The 2025 wave of EV rollouts has created a surge in component orders. According to a recent Statista report, the global gear motor market is projected to grow from $6.8 billion in 2024 to over $9.4 billion by 2028, largely driven by electrification of mode of transport. In China, where BYD and NIO lead the pack, local producers are ramping up production lines, leveraging low‑cost stainless steel alloys and precise machining techniques that keep them ahead of the technology curve.

Meanwhile, startups are redefining the gear motor’s role. Companies such as Lumen Robotics are embedding micro‑gear motors into autonomous delivery drones, enabling rapid take‑off and precise landings, while BlueWave Marine is licensing gear motor technology to let cargo ships switch from diesel to electric propulsion. As these novel applications multiply, specialized gear motors—compact yet powerful—are now influencing all sectors of the transportation economy.

Automobile assembly lines rely on synchronized motion to meet demand. Gear motors equipped with electronic speed controllers adapt instantly to variable loads—essential for tasks like automated lifting of car bodies, palletizing, and inspection. The adoption of “smart gear motors” that communicate through Ethernet/IP allows factory PLCs to modulate torque in real time, smoothing production flow and cutting downtime. The synergy between EV component suppliers and automotive OEMs is therefore more than a valve‑open relationship; it is a tightly coupled ecosystem where efficient power conversion translates into higher production yield and cheaper, lighter vehicles.

Looking ahead, several trends promise to elevate the gear motor’s role:

One of the most exciting frontiers is in marine and logistics. The trend toward “green shipping” is prompting the design of electric cargo vessels that employ reliable gear motor systems to convert low‑speed, high‑torque output from battery banks into efficient propulsion. By reducing mechanical losses, gear motors help these vessels meet strict emission targets and maintain high CM (contiguous maritime) fuel efficiency benchmarks.

The recent surge in EV adoption marks just the beginning of a broader shift toward electrified transportation and industrial automation. At the heart of this transformation lies the gear motor—an unassuming component that quietly transforms electrical energy into mechanical motion with efficiency and precision. As the demand for cleaner, faster, and smarter mobility grows, gear motors will also grow more sophisticated, finding new applications from autonomous drones to green shipping. For businesses and engineers, staying ahead means recognizing the gear motor not just as a mechanical accessory, but as a pivotal enabler in the drive toward a more sustainable future.

Leave A Reply

Your email address will not be published. Required fiels are marked